|

The

Basic's of

Welding 4130 Chrome Moly (Chromoly) Steel are Presented

on This Web Page

For other

4130 welding info

Click

TECHNICAL & METALLURGICAL DETAILS

Click

WELD COOLING RATE EQUATIONS

Click WELDING HEAT TREATED

4130 CHROME MOLY

Click

METALLURGICAL DEFINITIONS

Click "How To Pronounce" CHROME MOLY

Click

WELDING A BETTER STEEL; HY 130

Click

DEFINING "EFFECTIVE HEAT INPUT"

CLICK to See Side Bar Below Regarding the

Strength of Welds Made with ER70S-2 versus ER80S-D2

|

The Editor of the American Welding Societies Monthly Journal Asked Me To Write and Article on Motorsports Welding for the March 2018 Issue. The Editor of the American Welding Societies Monthly Journal Asked Me To Write and Article on Motorsports Welding for the March 2018 Issue.

This is a PDF of what was published. It compares differences in NHRA with NASCAR chassis construction. Where NHRA top classes use high strength 4130 tubing, NASCAR belives in a "Bend Before Break" design. They specify mild steel tubing and the min wall thickness that can be used!

CLICK PDF ICON  RIGHT or pic to Download a PDF. RIGHT or pic to Download a PDF. |

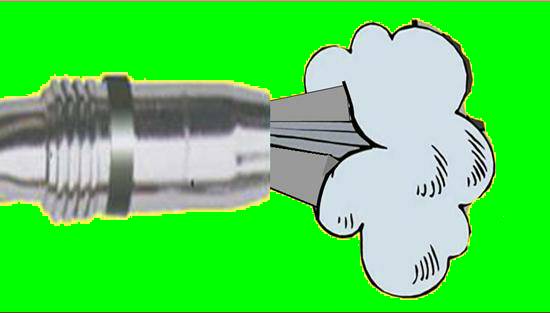

Our patented GSS provides better quality weld starts by reducing shielding gas turbulence. For short welds, excess turbulence can last for much of the weld. The GSS cuts gas waste using a small ID, heavy wall thickness hose incorporating a peak flow rate limiting restrictor. Over 10,000 are in use. Our patented GSS provides better quality weld starts by reducing shielding gas turbulence. For short welds, excess turbulence can last for much of the weld. The GSS cuts gas waste using a small ID, heavy wall thickness hose incorporating a peak flow rate limiting restrictor. Over 10,000 are in use.

Check out our FB3 & FB4 GSS models.

Alert !!

Argon Prices tripled in the Past Several Years! Alert !!

Argon Prices tripled in the Past Several Years!

Air Products announced Argon price increases of 20% in three consecutive years; 2017, 2018, 2019 and 35% in 2020!!

A major producer of Cryogenic Tanks and a leading Airplane Builder have purchased over 300 GSS's for their TIG Welders to improve weld start quality and cut gas use 30 to 40% .

Video-Welding 4130

CrMoly |

|

4130 was widely used in WWII airplanes! It was welded with oxyacetylene as TIG welding had just been invented! With oxyacetylene the material is being preheated and cooling is slow so the relatively high  carbon 4130 was considered very weldable. With TIG or MIG there is is usually no preheat used and cooling is very rapid leading to possible hard and brittle welds without employing precautions. carbon 4130 was considered very weldable. With TIG or MIG there is is usually no preheat used and cooling is very rapid leading to possible hard and brittle welds without employing precautions.

Of interest, in WWII about 40% of the workforce were women. This is a picture from War Archives is of Ann Rosner oxyacetylene welding an aircraft supercharger duct at Ford's Willow Run plant.

When writing "Advanced Automotive Welding" for CarTech I talked with Gene Golliet about his welding of 4130 aircraft tubing in shops in Southern California during the War. Some experimental aircraft still use and prefer that welding process.

|

Welding 4130 Chrome Moly Steel for Race Cars

During

the WW II era 4130 high strength steel was used for some aircraft components. At

that time

oxy-acetylene was the welding process of choice for many of these items. The preheat and slow cooling

inherent with that process made welding the nominal 0.30 carbon steel

relatively straight forward (assuming one could oxyacetylene weld!). However with more modern welding process like TIG and

MIG, the cooling rates can be much faster and care must be taken to avoid

forming high hardness and brittle Martensite on cooling transformation. On heavier

sections preheat and post weld heat treatment should be used. With the

proper post weld heat treatment strengths of 200,000 psi can be achieved with

reasonable toughness by tempering the Martensite that forms in the heat treating

process. However when welding race car tubing, preheat is not often used

nor are the parts post weld heat treated. During

the WW II era 4130 high strength steel was used for some aircraft components. At

that time

oxy-acetylene was the welding process of choice for many of these items. The preheat and slow cooling

inherent with that process made welding the nominal 0.30 carbon steel

relatively straight forward (assuming one could oxyacetylene weld!). However with more modern welding process like TIG and

MIG, the cooling rates can be much faster and care must be taken to avoid

forming high hardness and brittle Martensite on cooling transformation. On heavier

sections preheat and post weld heat treatment should be used. With the

proper post weld heat treatment strengths of 200,000 psi can be achieved with

reasonable toughness by tempering the Martensite that forms in the heat treating

process. However when welding race car tubing, preheat is not often used

nor are the parts post weld heat treated.

Most of the tubing used

for race car construction is referred to as normalized. This refers to the

heat treatment and cooling rate the tubing was subjected to in manufacture.

Most normalized tubing will range in tensile strength from 95,000 to 110,000

psi. This can be welded with the proper filler metals to achieve similar

strengths. Although there are more weldable grades of steel (those with

lower carbon content from 0.06 to 0.15) in the 100,000 to 115,000 psi

tensile strength range readily available for plate and sheet, 4130 remains a

commonly used grade for tubing. Just be sure to take the precautions noted

when welding.

The following is extracted from an article I wrote for the American Welding

Societies technical journal called "The Welding Journal". It has

additional information to that presented in the publication. You can see the article in the 2003 April issue of the AWS Welding Journal:

|

PROPER FILLER METAL CHOICE FOR WELDING 4130

In the mid

1970’s, while managing an R&D group for a leading welding shielding gas/filler metals manufacturer, a

phone call was received from a dragster chassis builder. They wanted to weld

4130 tubing and needed a filler metal suggestion. Being a “car buff,” a

number of alternatives were considered to provide the optimum solution. After

careful review of their requirements and desired welding practices, the solution

was defined. They were welding 4130 normalized tubing, it would not be heat

treated after welding, preheat was not desirable and most of the weld joints

were intersecting tubes that required fillet welds. The best filler material to

use was a low carbon alloy now called ESAB Spoolarc 65 (meeting an American

Welding Society (AWS) ER70S-2 specification). The main objective is to produce

porosity and crack free weld deposits. This welding alloy has a very low carbon

content, nominally 0.06, which can handle dilution into the relatively high (in

terms of weld metal), 0.30 carbon in the 4130. The resulting diluted weld

deposit has a tensile strength of approximately 590 to 620 MPa ( 85,000 to

90,000 psi.) The actual strength will depend on the amount of dilution with the

4130, weld bead size and material thickness. This is usually an under match for

the 4130 tubing which could have a 760 to 800 MPa (100,000

to 115,000 psi) tensile strength depending on how the material was processed.

[Added Note: some normalized 4130 tubing may be only have a 90,000 psi

tensile strength, it depends on the manufacturer] However, if extra joint strength is required, a slightly larger fillet size or

gussets can be employed. In addition, this welding wire contains small amounts

of aluminum, titanium and zirconium. Although these elements were initially

added to handle welding over mill scale, they also contribute to a less fluid

weld puddle. The benefit to the welder is, it is easier to make out of position

welds. Note, it is suggested all welding on 4130 be performed on ground

surfaces free of oil or grease (to keep the hydrogen levels as low as possible). In the mid

1970’s, while managing an R&D group for a leading welding shielding gas/filler metals manufacturer, a

phone call was received from a dragster chassis builder. They wanted to weld

4130 tubing and needed a filler metal suggestion. Being a “car buff,” a

number of alternatives were considered to provide the optimum solution. After

careful review of their requirements and desired welding practices, the solution

was defined. They were welding 4130 normalized tubing, it would not be heat

treated after welding, preheat was not desirable and most of the weld joints

were intersecting tubes that required fillet welds. The best filler material to

use was a low carbon alloy now called ESAB Spoolarc 65 (meeting an American

Welding Society (AWS) ER70S-2 specification). The main objective is to produce

porosity and crack free weld deposits. This welding alloy has a very low carbon

content, nominally 0.06, which can handle dilution into the relatively high (in

terms of weld metal), 0.30 carbon in the 4130. The resulting diluted weld

deposit has a tensile strength of approximately 590 to 620 MPa ( 85,000 to

90,000 psi.) The actual strength will depend on the amount of dilution with the

4130, weld bead size and material thickness. This is usually an under match for

the 4130 tubing which could have a 760 to 800 MPa (100,000

to 115,000 psi) tensile strength depending on how the material was processed.

[Added Note: some normalized 4130 tubing may be only have a 90,000 psi

tensile strength, it depends on the manufacturer] However, if extra joint strength is required, a slightly larger fillet size or

gussets can be employed. In addition, this welding wire contains small amounts

of aluminum, titanium and zirconium. Although these elements were initially

added to handle welding over mill scale, they also contribute to a less fluid

weld puddle. The benefit to the welder is, it is easier to make out of position

welds. Note, it is suggested all welding on 4130 be performed on ground

surfaces free of oil or grease (to keep the hydrogen levels as low as possible).

Several years after making this

suggestion, when looking at a catalog from the dragster chassis

manufacturer, it was interesting to note they were advertising their use of the

ER70S-2 filler metal for their 4130 welding. In fact, they were offering it for

sale for those customers purchasing frame parts and doing their own welding!

The Internet was searched to

see what current recommendations were being made for joining 4130 tubing.

Several hundred sites were found that recommend the ER70S-2 welding rod/wire alloy.

It was the predominant recommendation. Typical of the Internet however, there

were many improper descriptions of why this alloy should be used and several

incorrect recommendations.

Need a higher

strength deposit? If a higher strength weld is required for perhaps a butt weld

that cannot be reinforced, strengthened with a gusset, or put in a less

critically stressed area, there are possible solutions. The use of Spoolarc 83, which contains 0.50 Moly, will provide a weld deposit with higher

strength. When diluted into the 4130 base material a weld tensile level of 760

to 800 MPa (110,000 to 115,000 psi) can be achieved. If this higher strength

welding wire is employed, a minimum preheat of 65 degrees C (150 degrees F) is

suggested. Weld strength can increase to a level slightly higher

than the normalized 4130 with Spoolarc 83 (AWS ER 80D-2). Do not use an austenitic

stainless steel such as an ER308L, (which is recommended on some Internet

sites). Diluting this or similar austenitic stainless alloys with 4130 can lead

to cracks. Also, consider that providing a higher strength weld deposit cannot

compensate for the reduction in strength that will occur in the parent metal

immediately next to the weld deposit.

For Parts to

be "Heat Treated" (meaning carefully raising the part to 1600 F; Quenching in

water; then Reheating precisely to 1000 F; then Slow Cooling) After Welding:

Note: modified with additional information obtained since writing this article.

Click to See Detailed Explanation:)

If the part is to be used for

potentially high impact, structural applications and will be

heat-treated after welding, a matching chemistry or matching hardenability filler metal to the 4130 should be employed.

This may be a filler metal with somewhat lower carbon but increased moly,

chrome, manganese etc. Because of the relatively high

carbon, a minimum of 200 degrees C, (400 degrees F) preheat and very slow

cooling after welding should be used to avoid cracking. Heat treating

after welding refers to the finished welded part being heated to 870 degrees C (1600 degrees F), quenched in oil or water then

tempered back to say 540 degrees C (1000 degrees F). A complex cycle, but

this will result in a tensile strength of approximately 1035 MPa (150,000 psi).

Since the weld is the same chemistry as the base material, it and the

heat affected zone will have the similar properties as the base material when

heat-treated. All critical welds of this type should be inspected for internal

soundness to assure they are free from cracks.

|

|

End Of Abstracted Article

OTHER PROBLEMS ENCOUNTERED

In addition to the filler metal selection issues mentioned, some additional

cautions should be followed. Many fabricators use TIG

welding

and make very small, concave fillet welds. There seems to be a

feeling that the smaller the better. This raises several concerns.

First there is little filler metal used to make these very small welds.

Therefore the weld consists mostly of the high (by welding standards) carbon

from the 4130 base material. This can cause cracking since there is no preheat

or postweld heat treatment being used. Also cooling rates for these small welds,

especially when using TIG, can be quite high. Therefore one suggestion I

had made in the article (removed from this abstract) was that some

stainless steels filler materials could be used. This is also mentioned on

a number of Internet sites. However with these small fillet welds there is

only a small amount of stainless filler in the deposit and possibly a

significant amount of the high carbon base material. This combination can

lead to a crack sensitive deposit. It is suggested stainless filler metals

not be used for welding 4130. welding

and make very small, concave fillet welds. There seems to be a

feeling that the smaller the better. This raises several concerns.

First there is little filler metal used to make these very small welds.

Therefore the weld consists mostly of the high (by welding standards) carbon

from the 4130 base material. This can cause cracking since there is no preheat

or postweld heat treatment being used. Also cooling rates for these small welds,

especially when using TIG, can be quite high. Therefore one suggestion I

had made in the article (removed from this abstract) was that some

stainless steels filler materials could be used. This is also mentioned on

a number of Internet sites. However with these small fillet welds there is

only a small amount of stainless filler in the deposit and possibly a

significant amount of the high carbon base material. This combination can

lead to a crack sensitive deposit. It is suggested stainless filler metals

not be used for welding 4130.

Making an analysis of the resulting weld chemistry for varying amounts of filler

metal dilution creates a scary scenario at low amounts of any stainless

filler alloy. When I discussed the use of stainless filler metal making

these small fillets in 4130 tubing with a friend who is an acknowledged

"worldwide stainless welding expert," he cringed! As he said, the

suggestion that 312 stainless filler be used is based on at least 40 to 50%

filler metal diluted in the high carbon material. If you make almost an

autogenous TIG weld (no filler metal) and add just 20% of even 312 stainless you

get a Martensitic deposit. You do not obtain the desired

microstructure on which folks base their recommendation for a particular

stainless alloy rod being acceptable. I have had race car fabricators say

they like to use stainless filler because it makes the weld stand out and look

good on unpainted frames they sell! Not a good reason since it could also

contain cracks!

|

With only small additions of these filler alloys to the weld deposit there

is a high percentage admixture of 4130. In these very small deposits

this can create a crack sensitive metallurgical structure. In fact for

these small welds the use of ER70S-2 becomes even more of a preferred

suggestion.

ER70S-2 with its low carbon and leaner Manganese and Silicon alloy than some

other of the rods/wires often recommended as usable such as ER70S-6, creates

less of a dilution problem.

Small cracks and the presence of a brittle Martensitic structure in

these welds can lead to failure or can cause a brittle fracture when

subjected to a crash. See the welds in the photo of the dragster

chassis. I don't know what filler wire was used to weld these joints,

what little there was, but the fillets are very small. It

does not appear very much if any bending took place in the structure before they failed!

|

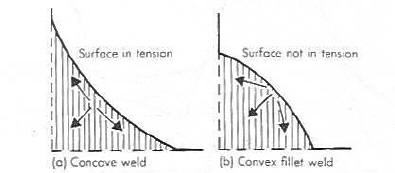

Another problem created with small concave fillet welds is when they cool the

surface is put in tension. This makes it susceptible to cracks especially near

the toe of the weld where it is very thin. (Sketches from article by Omar

Blodgett)

Bottom line is use larger flat fillets to assure less dilution with

the 4130 and a less crack sensitive shape. |

|

Side Bar

Had an interesting

conversation with two folks who have extensive experience welding 4130

tubing for race cars. One said his company was asked to help a

large racecar team solve welding problems. He found they were welding

with a special stainless rod "Super Missile Weld" (a 312 stainless steel rod with a fancy name.) Because of

the small TIG fillet welds they were making with very little added filler

rod, they were not getting an austenitic stainless steel weld deposit

because of excess dilution with the base material. Instead they were getting

a high chrome, brittle ferritic deposit! He took in some carbon steel

rod (the one we suggest, ER70S-2) but told them this was a "very special"

rod that would solve their problem. It did! " Just because it costs

more does not make it better!"

The other fellow who has

fabricated a number of sportsman and other drag cars and weld repaired a

number of other 4130 race cars. He saw a number of weld failures

on some chassis caused

by the very small concave fillets that had been used .

He also said some welds were made with poor, cold MIG Short Arc welds that

were not fused properly to the tubing. Both very bad welding practice.

|

|

STRENGTH OF ER70S-2 WELDS

The following discusses AWS TIG/MIG Filler Metal

Specifications that are often misinterpreted in Welding Forum comments:

-

The Specification that defines carbon steel wires

and rods, including ER70S-2, for MIG and TIG welding is AWS 5.18. ER80S-D2

is covered by AWS A5.28, for Welding Low Alloy Steel.

-

Both Specifications require reporting the tensile strength

from a weld made in a ¾-inch thick, mild steel weld

joint having a 45-degree V bevel angle, gapped ½-inch on a steel backing

bar. It requires many weld passes to fill this joint minimizing any

effects of the base material on weld properties. Each weld pass is

made at a defined (by the Specifications) amperage, voltage and travel

speed.

-

These welds do NOT increase in strength by mixing with

the relatively high carbon 4130 (by welding standards, it's high) as

occurs when making single pass fillet or butt welds in that material. The

weld strength in a single pass diluted weld in 4130 will be higher. The

exact strength achieved depends on the amount of rod added to the melted 4130,

joint type and thickness, welding parameters used etc.

-

Both Specifications define a minimum

tensile strength, i.e. ER70S requires a minimum

of 70,000 psi (note 1,000 psi = 1 ksi) and for ER80S - a minimum of

80 ksi. It does not say what weld strength will be produced; just the

minimum to be classified in that category. The specific

chemical range for a particular alloy (S2, S6, S7 etc) is also

specified.

-

The following data are AWS Specification weld test results

from ESAB (data is from Fig. 4-52, in my recently published book

Advanced Automotive Welding

that also discusses the implications in detail):

|

TIG, MIG, or Base |

Rod, Wire or (Base) |

Tensile Strength,

ksi |

Elongation,

% |

Impact Strength;

ft-lbs |

| TIG Weld |

ER70S-2 |

82 |

31% |

170 |

| MIG Weld |

ER70S-2 |

82 |

28% |

45 |

| MIG Weld |

ER80S-D2 |

110 |

22% |

85 |

| Base Material |

(Normalized 4130) |

~90 |

~25% |

~60 |

|

|

Bottom Line:

Even when not diluted with 4130, ER70S-2 has a tensile strength

just 9% under typical Normalized 4130. ER80S-D2 has a strength, with

no dilution with the higher carbon 4130, that is 22% higher than Normalized 4130.

Significantly higher strength weld metal than base metal may cause a

weldment, when stressed under load, to yield excessively or initiate

failures in the heat affected zone.

The elongation of Normalized 4130 (a measure of ductility) is

less than the very ductile ER70S-2 weld. The higher strength ER80S-D2 weld

has a lower elongation than the base material.

The impact properties of a TIG weld made with ER70S-2 are

excellent at 170 ft-lbs. Note, the reason TIG welds have higher impact toughness

than MIG welds made with the same alloy filler metal is discussed in the

Advanced Automotive

Welding book. |

|

CHECK WELD QUALITY

It is very important to check

weld quality and understand the types of defects that could be encountered.

Check your weld procedures and keep them consistent. You should make some

sample welds and bend them to destruction to assure failure occurs only after

considerable bending has taken place. Look for porosity or cracks that may

have been present in the weld. It would be a wise investment to hire the

services of an American Welding Society (AWS)

Certified Welding Inspector (CWI). There are some 25,000 registered.

In fact many of them are members of the 65,000 member AWS. They can

advise on procedures and what to check for such as small undercuts at the weld

toe of fillet welds that can lead to premature failure.

Consistently following the

proper weld procedures and knowing how to check for possible weld problems is of

major importance.

Closing Suggestion

When welding 4130 chrome moly in the

normalized condition, AWS ER70S-2 filler metal, with its low carbon content is

the proper choice. Make sufficiently large fillets and make them flat, not

concave. If the part is to be heat-treated after welding, then a

filler metal matching the 4130 chemistry should be employed. This requires

preheat and special precautions to avoid cracking.

Be sure to employ the skills of a qualified

welder who has experience welding this material. Also inspection of the

final welds by an Certified Welding Inspector (Certified by The American Welding

Society) is highly recommended.

(Welding Mild Steel Chassis's or Roll Bars? Click Here) |

|

Improve Weld Starts

and Save Money by Eliminating The

"Gas Blast" at MIG Weld Starts That Causes: Improve Weld Starts

and Save Money by Eliminating The

"Gas Blast" at MIG Weld Starts That Causes:

1)

Inferior Weld Quality and Excess Spatter

- due to the air pulled into the gas stream

2)

Shielding Gas Waste

- typically 50% of gas used

See Patented

Gas Saver System (GSS)

Solution

GSS

Works for TIG Welders with Foot Pedal or Thumb Control

|

FREE

Technical Paper Available Entitled; "MIG Shielding Gas Control and

Optimization" (or Everything You Didn't Know You Needed to Ask About

MIG Shielding Gas Control!) It Summarizes Key points in this Web Site

and numerous Technical Presentations made in US and International Welding

Conferences about the gas shielding problems and solutions. FREE

Technical Paper Available Entitled; "MIG Shielding Gas Control and

Optimization" (or Everything You Didn't Know You Needed to Ask About

MIG Shielding Gas Control!) It Summarizes Key points in this Web Site

and numerous Technical Presentations made in US and International Welding

Conferences about the gas shielding problems and solutions.

CLICK ICON for PDF DOWNLOAD |

|

Stop

Wasting Shielding Gas!!

See YouTube Videos

Including Our Patented MIG Shielding

"Gas

Saver System" (GSS)

The

Basic's of

Welding 4130

were presented on

this page:

Click for

TECHNICAL & METALLURGICAL DETAILS

Click for

EQUATIONS

defining weld cooling rate in tubing

Click for

WELDING HEAT TREATED

4130 CHROME MOLY

Click for

METALLURGICAL DEFINITIONS

Click for

WELDING A BETTER STEEL; HY 130

|

|

Why MIG Gas Waste

Detailed Review of GSS

Short Overview of GSS-90 Seconds

What User Say About

GSS

Welding Race Cars

Rat Rods-Then and Now

Welding: Go Green

Engineering A

Pro Street / Street Rod

|

|

ONE PAGE SUMMARY

PURCHASE

PRODUCT

FREE Corvette Accessory Installation Info

Miller TM is a trademark of ITW

Corporation |

▲HOME

|